I made the mast hinge improvement this past weekend and it was a complete success!

Firstly, we paid a surprise visit to MG Metals who had a very fine piece of aluminium alloy bar. I think they were a bit puzzled by me and Dad just turning up, but were very helpful and sorted us out in five minutes. It wasn’t so easy to buy stainless-steel machine screws. Screwfix seem to have given up selling screws. Fortunately, B&Q had a few. We ended up with 5mm pan-head screws and a few countersunk screws for fixing through the hinge outer.

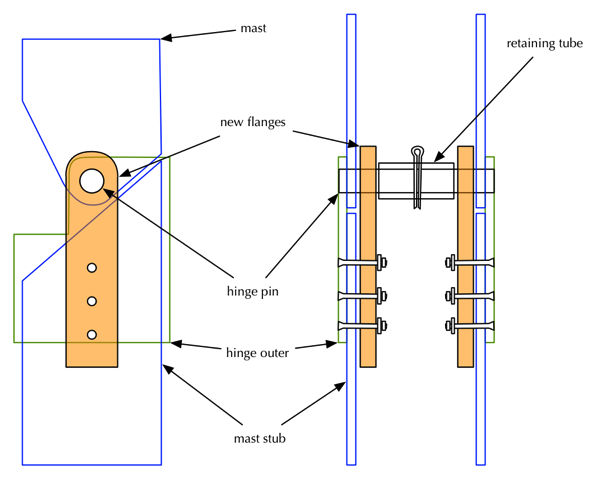

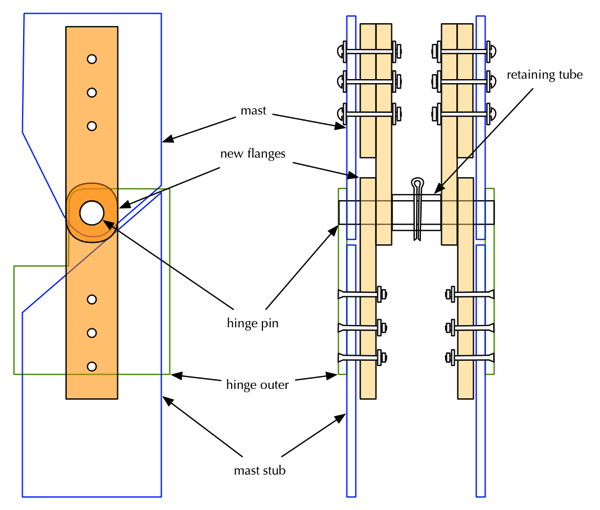

The first step was to work out an appropriate length for the flanges. We settled on 200mm. Dad suggested we put as six screws through the mast in each flange, and stagger them for strength. I cut a single 200mm flange and we drilled a centred 12mm hole at the top for fitting. Here it is hanging into the mast stub on the hinge pin I’d already had made, with the mast folded down and resting on the back of the boat.

I found positions for the six screws and drilled 5mm holes in the flange. Then came the nerve-wracking stage of drilling holes in the mast. A committing move. I did this by hanging the flange from the pin on the outside of the mast, aligning it carefully, then duct-taping it into position. I was then able to drill through the screw holes and through the mast. After that, I put the screws through and nuts on the back to test the fit. It took a bit of wiggling and everything was very tight, but I was able to get the pin into position. Here’s the result.

At this point I made a second flange, using the first as a template, and repeated the procedure. I also made some thin spacers from plywood so that the flanges didn’t press directly onto the mast. I shaped these with a surform so that their curve fits the mast pretty well, with a flat face against the flange. This gives the flanges a tiny bit of movement but will avoid their edges cutting into the mast when the whole thing flexes. The movement helps with aligning the hinge pin.

This all took up most of Friday, but we were able to raise the mast on Saturday morning in time for my brother’s family to visit. We did this with guy ropes either side, but it already felt pretty steady, and there was no way that the pin was going to escape.

However, we were unable to drop the tight-fitting mast sleeve over the hinge. My screws had spread the hinge outer a little, and it was already an almost perfect fit. We cured this by drilling the holes for the top four screws to 5.5mm, allowing the hinge outer back to its original position.

My niece was particularly keen on the boat and set to work scrubbing the decks, though I think mostly she liked throwing water around and playing with the pumps.

On Sunday I made the two upper flanges and spacers, again using the first flange as a template. By this stage I was getting pretty quick, and drilled the mast with confidence. Because there’s a ring here to support the mast sleeve, there was only room for four screws. Also, with the flanges so close together, it became impossible to put nuts on the back of the screws! At this stage, Dad suggested capturing the nuts within the flanges. I drilled 8.5mm recesses into the flanges and (gently) hammered in nyloc nuts, with Duralac to prevent electrolytic corrosion between the stainless steel and aluminium.

This made assembling the whole thing much easier: I simply had to screw in the machine screws from outside. I also ended up drilling out all the holes to 5.5mm to allow the flanges to move around a bit more and let the pin through without enlarging the 12mm holes at all.

Time for final assembly. I dismantled the whole thing, treated the wooden spacers with three coats of exterior wood preserver, painted Duralac into all the holes, and screwed everything together. Finally, the pin went into place with a few gentle blows from a mallet — just right. Here’s the result.

The red stuff is my blood. And with the temperature at over 25°C there was quite a lot of sweat involved too.

And here you can see the screws in place painted with Duralac. Blood, sweat, and Duralac pretty much sums it up.

But what fantastic results! We raised the mast, again with guy ropes just in case. It felt rock solid. Once we had it vertical I asked Mum and Dad to be ready on the guys and tried to push the mast from side to side. Nothing. In fact, I was unable to get it to wobble at all in any direction, except backwards in order to fold it away. Here’s a picture of the hinge with the mast raised.

The mast sleeve slid neatly into place over the whole thing, making everything even more rigid. You can see the sleeve covering the hinge in this picture of the rig reefed down to three panels.

During that afternoon I had to make several changes to fittings at the top of the mast. No problem: down with the sail, up with the sleeve, and just fold the mast down. No need for help. It feel like about 15-20kg of force: no problem at all. And I’m pretty sure it’ll work just as well on a canal or river.

So now Tammy Norie can duck under bridges with ease, opening up a lot of opportunities for inshore exploration.

Many thanks to everyone who suggested solutions, but especially to Dad who gave me advice at every step of the way and taught me to use his tools. Hurrah for engineering!