After spending a good 100 hours constructing my Hebridean wind vane I grew quite frustrated when it started to go wrong, especially after such initially promising results. However, after some very useful comments from readers I set about constructing a temporary replacement pendulum.

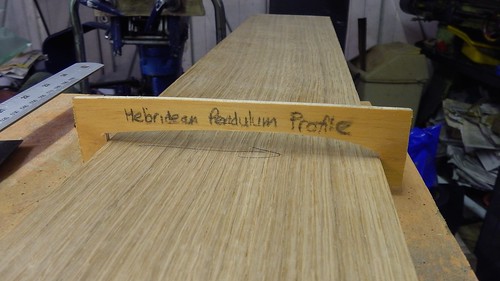

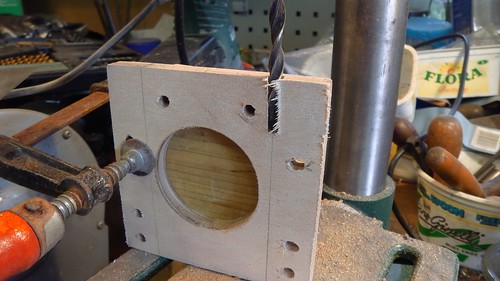

I started out with some 18mm plywood and a couple of hardwood blocks bought from the local Hubo.

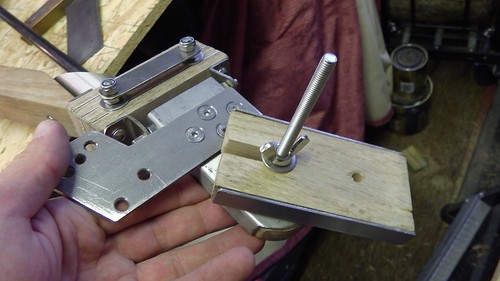

I didn’t glue the blocks to the plywood, instead using four big stainless steel screws through each, being careful to offset them slightly so they didn’t clash.

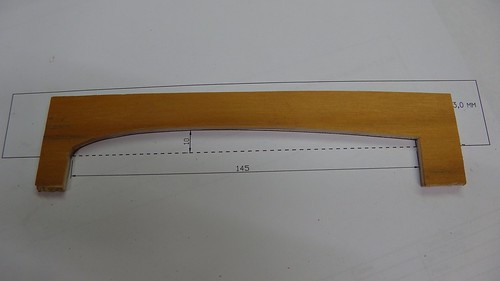

Then I marked off 9mm from each side of the leading and trailing edges, sharpened my plane, and set about adding a 45° bevel to the leading and trailing edges. The plywood makes this easy to get right since it has a built-in gradient.

I noticed there was a slight curve in my plywood, but hoped that removing the pendulum balance cut-out would prevent this being an issue. I was expecting to have to add some balance later.

I put on a few coats of Cuprinol Ultimate to help keep the water out.

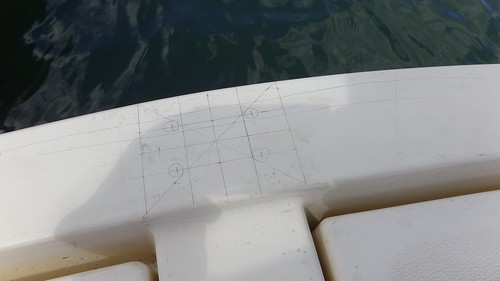

I was deliberately doing all the work in Tammy Norie’s cockpit, to see what it was like. Well, this is what the cockpit was like, anyway.

I attached the pintles and mounted the pendulum onto the Hebridean frame.

Later that day I sailed from Harlingen to Den Oevre. Actually, I mostly motorsailed due to adverse wind and current, and the need to make the weather window in the North Sea. But I did spend about an hour trying out the Hebridean on various upwind courses in what was about a force 3 or 4.

It seemed to work really well. With the linkage disconnected the pendulum was stable and would return to the centre position. With the linkage connected and the vane in place, but no tiller connection, the vane behaved itself very well. Attaching it to the tiller worked just fine and the boat steered nicely. There was no obvious lack of sensitivity, though truly light wind tests have yet to come.

After picking up Martin Roberts at Den Oevre and motoring out past Den Helder we reached our departure point, and I set up the Hebridean for downwind.

It worked well, and continued to work for the entire 36-hours that followed, taking us across the North Sea. For the second half of the trip it was set to a dead downwind course and took us through some pretty big and steep wave conditions.

The only problems were with the control line setup. I’d used some simple twine to attach various blocks and eyes on a trial basis, and these chafed through after 24 hours of continuous action. This put us off course temporarily on a couple of occasions but nothing serious went wrong.

We didn’t disconnect the Hebridean until we had to cross the infamous bar on the river Deben, and I lifted it off completely when we put in to Tide Mill yacht haven. Looking at it then, it was clear that the plywood had curved further, but unlike the original pendulum this didn’t cause any noticeable problems.

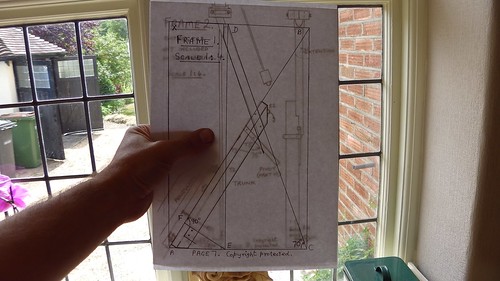

I spent a lot of time wondering about all this and discussing it with my crew. We went over all the suggestions, John Fleming’s instructions, and John’s feedback during the journey.

Our theory is this: John mentions that he expect instability that is dampened when the Hebridean is connected to the tiller. The thing is, the Coromandel has a small rudder and a very light tiller. We suspect that it’s simply not providing the damping that John expects, so that the pendulum flips out. Added to that, my pendulum seemed to develop a clockwise bias, and that made it always flip out in one direction almost immediately, overwhelming the vane. The simple unbalanced pendulum doesn’t require damping to stay in line, so it behaves much better on my little boat.

It might also be insensitive and fail in light winds, but it seemed to be doing the job in F3. I’ll know more when I try it out around the East Coast this month.

Anyway, I think we have discovered something important about the Hebridean and my boat, making the whole thing much more feasible for my Jester Challenge attempt. I now believe it can be made to work. And I’ve also proved I can repair it in the cockpit!