Last Saturday I attempted to sail from Wells-next-the-Sea to King’s Lynn as the first step of my plan to bring Tammy Norie to Cambridge. The weather wouldn’t let me.

I left Cambridge at 06:35 carrying a sheet of 6mm exterior plywood that I planned to use for improving deck fittings, and reached Wells just after 09:00.

I bought Imray chart Y9 of the Wash, paid the harbour and dropped some money in the charity trust box as promised. I spent some time preparing Tammy and chatting to my neighbours on the pontoon — mostly motor cruisers who felt it was too rough to go out. Indeed, on my way out and over the bar I met four scurrying in, several of them ignoring the cardinal and channel buoys in their hurry to get out of the waves.

It was a bit choppy. The wind was westerly force 6 and the waves were short and high with quite a few breaking at the Wells bar. Once out past the cardinal it wasn’t too bad, but once again Tammy failed to make any progress to windward in the short sea. I made an hour-long tack northwards, trying everything I could to make progress, but when I tacked back to see how I was doing I found I’d actually slipped downwind about a quarter of a mile.

The wind was only forecast to get worse. It was clear I wasn’t going to get to King’s Lynn at all, and that it would be dangerous to have Hunstanton on the lee in such conditions. I could run back to Sea Palling and abandon my Cambridge plans, or I could scurry back in to Wells.

At this point I was a bit worried about Wells. On the way out I’d noted I had over 3m of water in the channel, and since then the tide had peaked and dropped a metre below that, so I ought to have 2m going in, if I was quick. But the tide was falling all the time and if I made a mistake I could be in quite a bit of trouble.

My main fuel tank was also running very low at this point. I’d been unable to fill up because Wells has no petrol station. So I transferred 4 litres from the reserve into the main, lifting them both into the deepest part of the cockpit to avoid getting any water in the fuel.

I was unable to raise Wells harbour on the radio or telephone, but managed to chat to the friendly guys on the beach patrol RIB who were watching the holidaymakers on the nice sheltered beach at the entrance to Wells. They suggested I come in quick.

So I did. Tammy’s 5hp engine seems just about adequate for pushing her into the wind, waves, and ebb current on the westward turn over the bar. I’m very glad I didn’t go for a smaller engine, and I kind of wished I still had the 10hp monster that I broke earlier. I’m absolutely sure that I couldn’t’ve got back in with a yuloh or scull. Engineless I would simply not have had the choice to enter Wells. Perhaps one day I won’t be on a schedule.

By the time I was at the beach chatting with the beach patrol guys over the side it was too late to get back to the town. The suggested I anchor just south of the outer harbour, and so I found a broad spot that still had some water and threw the anchor over the side. By the time I’d dropped the sail and made a log entry I was aground in a lovely spot.

I spent the afternoon trying to remove the starboard middle stanchion and trying out some kite aerial photography. At about 22:00 I floated off and rode the very strong Wells flood back to the town, where my motor-cruiser friends were chatting and helped me tie up. “You must be exhausted,” exclaimed one, and I realised that they thought I’d been out at sea for twelve hours. I explained that I’d been on a sandbank for most of the day drinking tea and playing with a kite.

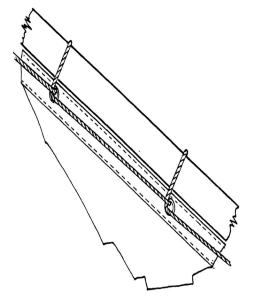

I spent most of Sunday fixing the stanchion. Briefly, here is what it was like in the morning:

and in the afternoon:

It is the prototype for upgrades to all the deck fittings, ensuring they are sealed and strong. I also fixed the tiller pilot, so it was an enjoyable and productive day. Even right inside Wells the wind was very strong, and nobody was going out.

I met an excellent chap named Alan in a temporarily mastless Maurice Griffiths boat called Stella Marie who had Haslar self-stearing gear “serial number 2” hanging off the back, and we had a very nice chat about the Jester Challenge and good places to visit in the Wash. At one point he mentioned that people used to have boat stamps in the old days, and I was able to produce mine and stamp his log book, much to our mutual enjoyment.

On the whole, getting stuck in Wells was no bad thing, and I’ll make another attempt on King’s Lynn as soon as the westerlies decrease.