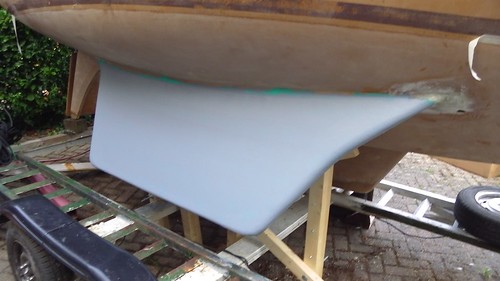

In my previous article I described how I removed, inspected, repaired, and faired the surface of Tammy Norie’s rudder. I was very pleased that this solved the riddle of Tammy’s “goosebumps” and eliminated osmosis as a cause. But I still plan to add an osmosis-preventing barrier coat to Tammy’s bottom, and the rudder is my second test area.

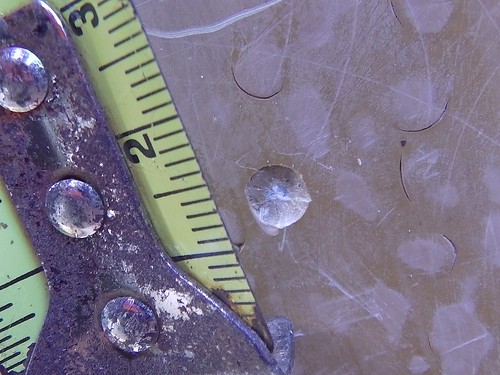

My first test area was the two keels. I had been planning to use International Gelshield as a barrier coat, and tried this out when I reinforced the keels earlier this year. I have to say I have not been impressed. It does seem easy to apply, but it also seems rather easy to remove! It’s very soft. Here’s a patch where I tried to fill a flaw on the keel, then (very lightly) sand it down to match. You can see through all the grey/green alternating layers back to the brown gelcoat.

I’ve also had problems where the ropes used to lift the boat on the crane had easily worn through the Gelshield. It just doesn’t seem like a very strong surface. It would certainly come off the next time I scraped away the antifouling.

So I have decided to try out an epoxy barrier coat instead, using West System’s instructions. An epoxy resin layer will be much tougher than this paint-like Gelshield. On the Facebook group “Sailing on a Shoestring”, I came across a couple complaining about all the trouble they were having removing an epoxy barrier coat, until they realised that they didn’t need to. That sounds more like it. It also helps that Mads Dahlke has made a detailed video about applying it to his yacht, Athena.

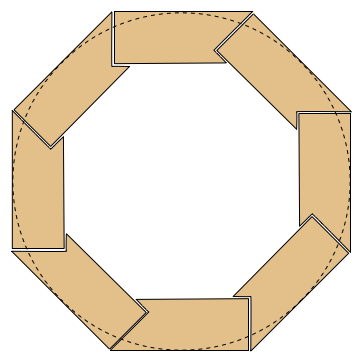

The main difficulty is that applying layers of epoxy is technically more tricky than applying Gelshield, which goes on like paint. Epoxy resin cures into plastic by a chemical reaction that is mostly influenced by temperature, unlike paint, which dries in the air. While the epoxy is soft you can’t add another coat, because the weight will just drag it down. But once it’s hard you can’t add another coat, because the new coat won’t form chemical bonds with the one underneath. In between these two times the resin is firm, but the surface is tacky. There’s a supposedly short period of time to work with. What’s more, a barrier requires six coats.

(In fact, you can add new epoxy over completely cured epoxy, but you have to wait until it’s hard enough to sand, then sand it all to create a mechanical bond. Since it took me six months to sand Tammy’s bottom, I’m not keen!)

The good news is that West System provide all of their excellent manuals online, including a detailed manual about osmosis repair and prevention. This includes a very handy figure for selecting the epoxy resin hardener chemical.

Since I’m often slowed down a lot by ME/CFS, I wanted to make sure I had plenty of time for coating. So I bought their 105 resin with their 206 slow hardener. Here it is set up in the kitchen over the radiator, so that it stays warm and runny.

West System do not recommend the use of 206 below 16ºC because it’ll cure very slowly. But that’s just what I wanted. I had an idea that if I was unable to get the job done in one day, as recommended, then it might stay tacky over a cold night.

I also managed to lay hands on pots of their 422 barrier coat additive. My usual suppliers, East Coast Fibreglass Supplies, didn’t have any and couldn’t say when they’d have more. Fortunately, the lovely folks at YouBoat in Gosport had two 500g pots. Even better, they were three years out-of-date, and I got them half price!

Now I happened to know from my reading on osmosis that barrier coat additive is usually made of finely ground minerals, so a few years sealed in a pot are unlikely to affect it. A quick look at the safety data sheet for 422 confirmed that it was made of aluminium powder and mica. Bargain!

I did a few calculations to work out the quantity of resin I’d need. I’ll summarise these for others.

West System say to use 8-10 mini-pumps and add 56g of additive, confusing volumes with masses. However, the specific gravity of the resin is 1.18, so I was able to make this conform as 20%-25% by mass. In practice, this was about one heaped teaspoon per pump, according to the kitchen scales.

West System say that one “B” pack of 4.55L mixed resin will cover 43-48m² of a non-porus surface. I calculate this as 8.5m²/kg. However, Mads Dahlke (in the video linked above) says that 10 pumps will cover roughly 2m², which is 7.1m²/kg. I’m not sure how he worked that out.

One side of the rudder is 0.2m², so that’s about 0.4m² overall, which works out as two pumps using Mads’ estimate. Convenient for mixing, but I did have some excess, so I think Mads is a bit conservative.

I’m not going to go over all the basics of how I applied the resin. For that, you can read the manual, watch Mads’ video (linked above), or even this brief one from West System.

What I will tell you is what I learned.

Firstly, don’t be put off. It’s pretty easy. I do recommend going through the process on a trial area, even a piece of scrap, so that you can get the hang of it and gain confidence.

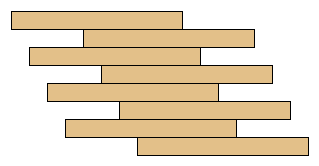

Epoxy is not paint. It does not dry; it cures. When you roll out paint it starts to dry immediately, so you tend to proceed, say, from top to bottom. But with epoxy it’s a bit more like you’re rolling out dough over the surface. The best method I found was to get the epoxy roughly spread around the surface, then spend time rolling it around until it was evenly spread. For some coats I even transferred it to the surface with a brush, then used the roller to finish the job. West System say to “increase the pressure” and this makes sense: spread it around with light pressure, then gradually increase the pressure to get a nice even layer. With my slow hardener I had at least an hour where I could still move the epoxy around on the surface and fix flaws.

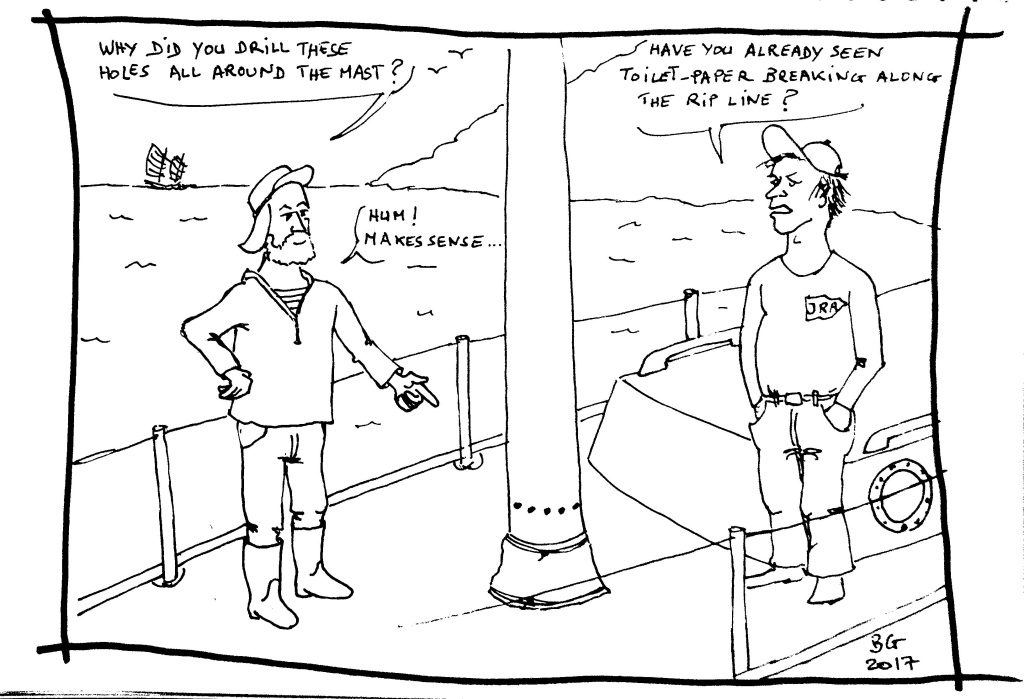

Here’s a picture of the first coat after I rolled it out like a painter.

As you can see, the coverage was good in some sections but not in others. This is where I discovered that I could just redistribute it with firm pressure from the roller, and get an even coat.

Don’t use tiny bits of roller. My calculations, based on West Systems manual, suggested that I should use one sixth of a 170mm roller for each coat. OK, I thought, but these small sections started to disintegrate. Later, I used a half roller, and this worked much better.

Avoid pouring new epoxy on to old, partially-cured epoxy. There’s some sort of reaction that causes the new epoxy to stiffen up fast, reducing working time dramatically. I only had one roller tray available, and while I mixed up the epoxy in a clean disposable plastic cup each time, I poured it onto the left-over tacky epoxy in my roller tray for two of the coats, and then had to hurry to get it rolled out because it was thickening up fast. I ended up finishing the job with a brush because rolling stopped working. After that, I stopped using the tray and used a brush to transfer the epoxy to the surface. When I do the hull I’ll use disposable roller tray covers to avoid this problem. Note that this reaction may be useful sometimes, and it also would seem to imply that the epoxy that you apply over a previous layer might cure faster than the first.

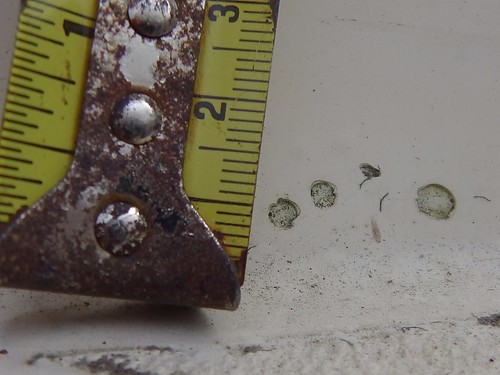

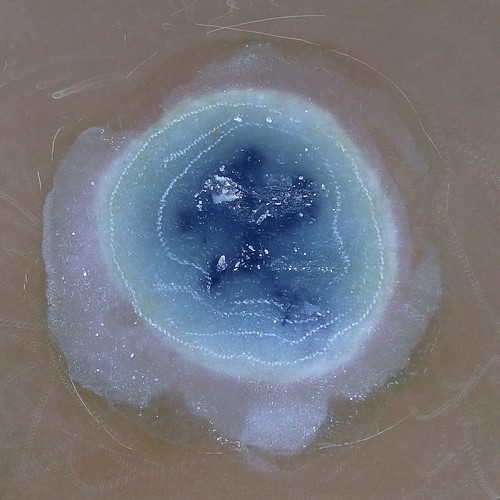

Here’s a picture of the surface after the second layer, which is the first layer containing the barrier coat additive. This layer had the new-epoxy-on-old mistake, but it still worked out OK for the rudder, which is only 0.4m² overall. If I had been trying to cover 2m² (as recommended) I would’ve been in trouble.

Don’t re-use rollers. If you squeeze them out after use then they seem to stay quite spongy even after the epoxy has set. But I found that the roller contained tiny lumps and flakes which transferred to the next layer. These are harmless, I’m sure, but they will mar the finish. They may introduce flaws that reduce the effectiveness of the barrier.

Slow epoxy stays tacky overnight. I only managed to get five coats done on the first day, but the temperature overnight was below 5ºC, and in the morning the surface was still a bit tacky. So I was able to apply a sixth layer. This confirms that the slow hardener might save me from failure if I can’t get everything done at once.

Tipping is easy. This is my first experience with the roll-and-tip method, where you roll out a coat, then lightly go over it with a dry brush or section of dry roller in order to smooth the surface. I thought this would require a lot of skill and a delicate touch, but it turns out to be very easy. Just apply gentle pressure and watch what’s happening and it comes out very nicely.

In fact, because each layer is translucent, this is a lot like a lacquer. It’s going to be a shame to cover it up with antifouling!

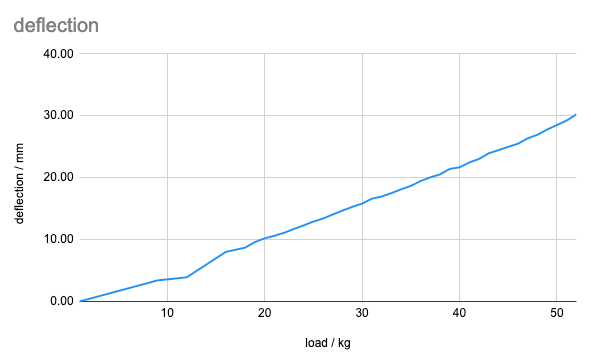

I kept notes as I went, to learn about the curing times. I’ve reproduced these here.

| Time | Temp / ºC | Pumps | Notes |

|---|---|---|---|

| 2020-10-09 08:55 | 9 | 2 | Tipped w. half of a half roller. Applied with 1/6 roller. Some excess. Some runs, tipped with brush. Applied too thick? |

| 10:05 | 14 | – | still fluid — soaked in to tissue |

| 10:20 | 17 | – | gel but fluid |

| 10:40 | 17.5 | – | ditto |

| 11:00 | 19 | – | just about ready |

| 11:30 | 20 | 2 | Batch went off almost immediately — contact with first batch? Uneven but spread and tipped with brush. |

| 12:05 | 19 | – | already tacky gel |

| 12:30 | 17.5 | – | still soft but tacky |

| 12:45 | 18 | – | ditto |

| 13:05 | 17.5 | – | firmer, very sticky |

| 13:30 | 17.5 | 2 | Better than last time but still short working time. Will try clean container. |

| 14:10 | 15 | – | Wet and not sticky |

| 14:45 | 12 | – | soft and sticky |

| 15:20 | ditto | ||

| 16:00 | 12 | 2 | Brushed on from fresh tub and rolled out. Good working time. |

| 18:00 | 12 | – | tacky |

| 18:20 | 10 | 2 | |

| 2020-10-10 07:00 | – | surface still a bit tacky | |

| 07:15 | 5 | 2 | Used heat gun to help spread |

| 19:00 | 5 | – | Very slight tackiness |

| 2020-10-11 08:00 | 10 | – | Surface set but able to dent with fingernail. |

| 2020-10-12 11:00 | 12 | – | Can no longer dent with fingernail, but can scratch. |

| [edit] 2020-10-14 | Can no longer scratch surface with fingernail. |

Finally, I’ll say that this was an exhausting exercise for me. It required attention for a full day with only short breaks. The actual area of the rudder and the physical effort probably don’t matter very much, I think. The concentration required and the inability to rest have left me quite fatigued, with recognizable post-exertional malaise. I will have to think quite hard about whether I can apply this technique to the whole boat with my ME/CFS. Perhaps I can recruit some helping hands for that job. Apply below.

EDIT: I’ve decided that I won’t attempt to apply this barrier to the main hull until the spring for several reasons:

- COVID-19

- It’ll be easier to schedule in weather with rising temperatures.

- Tammy Norie gets extra drying time over the winter.

Thank you for the offers of help. I’ll be in touch.