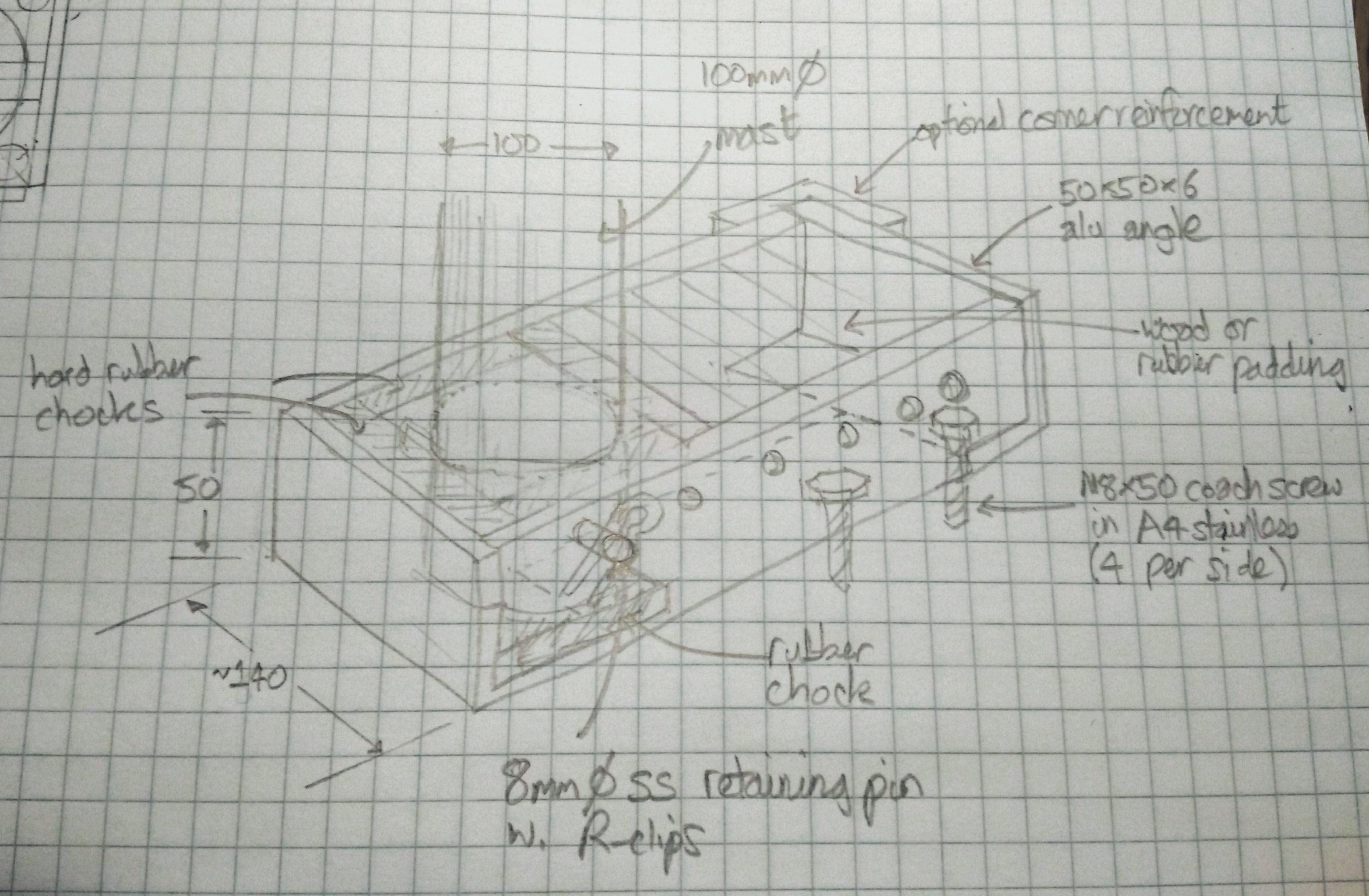

Thinking about a replacement mast for Tammy Norie has led me to become interested in the mechanics of wood-based composite materials. In fact, I have applications for this beyond building a mast. My plans for a new sail will require a yard, battens, and a boom. It would be most convenient if I could make these cheaply from easily-available materials, so that I can try out variations, and carry and make spares easily.

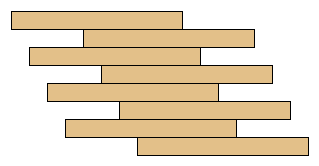

I did a few small experiments with jointing to make long battens back in 2017, but I didn’t record much information. I mainly concluded that I could make a strong yard, battens, and a boom of any size by gluing smaller pieces with large overlaps.

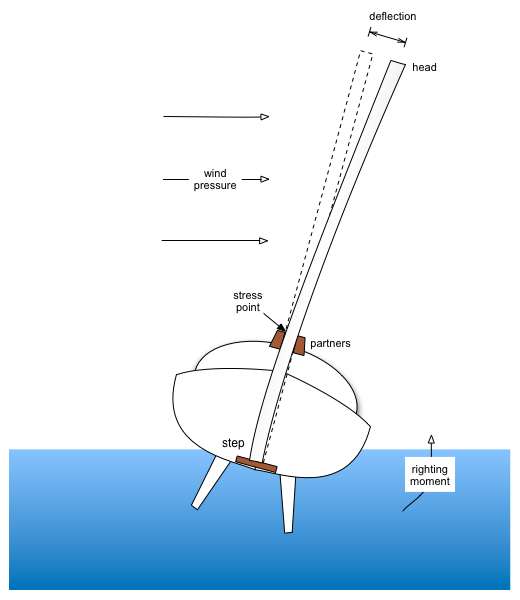

But a mast is much more critical. A mast breakage in the Solent is one thing, but a dismasting when sailing solo in the Atlantic could mean death. I need to know a lot more about my materials.

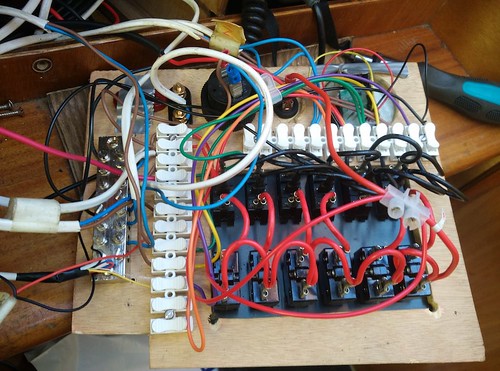

I have six sticks of softwood, all approximately 33mm × 18mm × 900mm. My plan is to carry out three-point loading tests to determine their properties when modified with composite layers, in particular glass and carbon fibre in epoxy resin. I’ll be measuring changes to elasticity, but also trying to determine yield stress (where they bend permanently) and ultimate (breaking) strength.

My test rig is a car crane capable of exerting over 500kgf. I’m using the legs of the crane to brace the samples, and one of the sticks as a fixed reference. A 100kg spring balance measures the force applied, and a micrometer measures the deflection.

The spring balance isn’t a very precise instrument, but I am hoping to measure fairly coarse changes in properties, so I’m not too concerned as long as it is reasonably consistent. The steel tube is there to provide a fulcrum for the bending test.

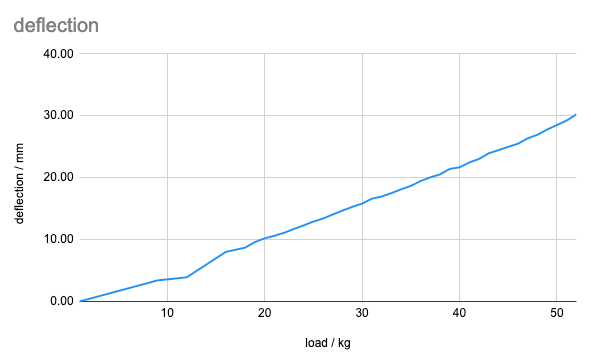

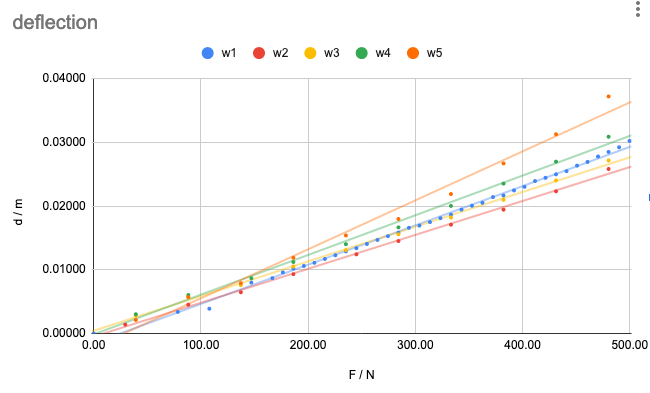

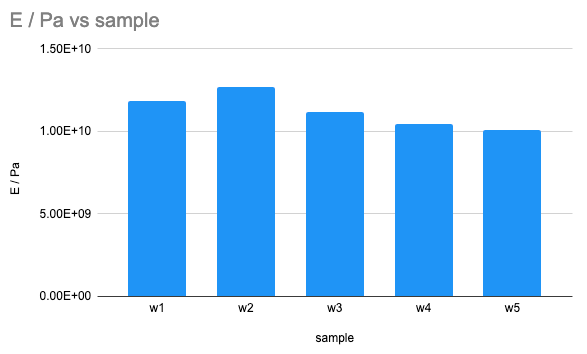

I measured the stick dimensions using the micrometer, and then Dad and I measured the deflection when we applied forces up to about 50kgf. We did this in steps of 2kgf for the first sample. This produced a nice straight line, validating Hooke’s Law and showing that we weren’t passing the yield stress. It also allowed me to calculate the actual Young’s Modulus for the wood at 11.9GPa, somewhat over the guarantee for C16 timber.

You can look at the measurements, calculations, and results yourself on this Google Sheet. I’ll be updating it as I go.

In the next step, I modified two of the samples by adding a composite to the top surface. I’m using 600g/m² unidirectional glass, and 200g/m2 unidirectional carbon fibre.

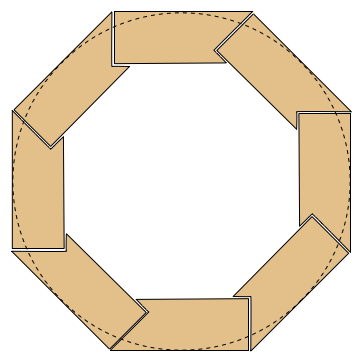

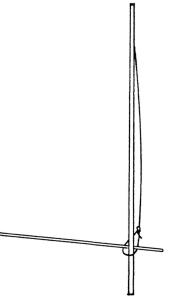

You might be wondering what this unusual unidirectional stuff is. As the name implies, it has almost all of the fibres running along one axis. For the mast in particular, I’m not very concerned with strength around the mast, but with reinforcing it against bending along its length. To do that, I want most of the fibres running up the mast, for the same reason you run the wood grain in that direction.

The Engineering Toolbox gives properties of unidirectional composites. It also quotes the proportion of resin to fibres. So to lay up the glass and carbon I calculated the mass of the fibres and applied, as best I could, the right amount of resin. It turned out that I needed to mix up about 4g more per sample, though. I noticed that the wood took up a couple of grams, and some amount was lost over the edges and in the mixing cup. I’m working with quite small quantities, so I didn’t expect this to be very accurate.

I laid up the fibre by first wetting the wood with epoxy, then laying over the fibre, pouring an even bead of epoxy along its middle, and using my squeegee to spread it evenly and push it in to the fibre. I tried to make only two or three passes to avoid overworking the epoxy and introducing bubbles. But I’m not making these samples too carefully. I’m trying to test what might happen to a real mast, whose surface area is about 2.5m², and so I want to apply a realistic amount of attention.

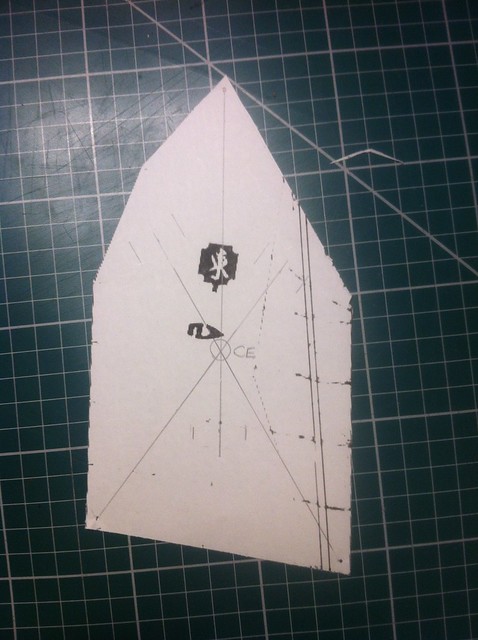

The results after curing aren’t too bad. Here’s the glass, which has come out very neatly. It’s about 0.9mm thick by the micrometer, but the surface is uneven so that’s not all composite.

The carbon seems harder to keep straight. The tape itself is not perfectly flat before layup, and it’s possible that the slight shrinkage in the epoxy during curing has some effect. I’ve never laid up carbon fibre before so there may be some trick I’m missing. On the other hand, slight waviness in the fibres might help to make the result more elastic and less brittle. I must do some more research on carbon layup. This is about 0.5mm thick by the micrometer.

Unfortunately, that’s it for now. Storm Alex has stopped all outdoor work for the moment. And it’s probably a good idea to let the epoxy cure for a few days before stressing it.

I can say a little bit about how I might make the mast if this works out well. Let’s suppose that most of the mast’s strength comes from 0.5mm of carbon on its surface. That makes it very vulnerable. A slash with a knife at deck level could bring the whole thing down! Clearly, the fibres need protecting, and it has to be possible to know when there’s been damage.

I will need to wrap the mast in another layer of some sort. That layer must be more elastic than the composite, otherwise it’ll end up taking the strain. It needs to be tough to resist damage. But also, it needs to show that damage. My current thought is to use another layer of fibre running around the mast (increasing elasticity), and to use epoxy pigments to dye the layers in contrasting colours so that wear is obvious to the eye from deck level. But it might be that some sort of elastic protective paint would do the job.

But this does make me wonder whether the fibres can be buried deeper somehow. I found this rather mysterious video of a birdsmouth wooden mast being assembled with some sort of embedded carbon rods.

I am of course not the first person to think of these things. I found this post from Eric Spoonberg in 2004 discussing issues with laying up carbon over wood. He refers to his web site, which is gone, but thank goodness for the Internet Archive, which has preserved this page of interesting free-standing mast projects using composites.

I can also make some predictions of the results. Firstly, there is the Rule of Mixtures, which gives some rather vague bounds using the volumes of the materials. But there is another method using the fact that the materials must all be under the same strain, because they are glued together. In fact, that’s one of reasons that composites work at all.

I’ll come back to this in another post, especially if it keeps raining.