It often seems to me that the function of an engine is to stop the boat dead, and do its best to prevent sailing activity. Maybe outboards sulk when installed on a Coromandel because they’re needed so little.

This is the story of what’s happened to the 1983 Honda BF100 that I obtained with Tammy Norie, and how I learned a lot about the insides of engines. You might want to skip it if you don’t want to learn too. Or you can skip to the later parts which involve ropes and the amazing icicle hitch! Believe it or not, this is nowhere near the full story.

First of all, Tammy Norie was neglected for the winter because of my health. That meant I never winterized her engine properly, and it has been in and out of the water in Fareham Creek twice a day for many months. Of course, when I went to start it, it wouldn’t run. Unlike the BF5, however, the carburettor was not clogged with fuel residue, and we were able to get it running quite quickly by dismantling and re-assembling the carburettor.

It was then that Dad noticed a bunch of corrosion-like material around the top of the cylinder head.

What’s more, we could see water seeping out of this area when the engine was running. The head gasket was leaking, and something nasty was coming out with the water. Uh oh.

This meant removing the head. On a 34-year-old engine that had not been dismantled for at least 30 years. The other sailors at the club were pessimistic.

We took the engine home and set it up using the trailer as a stand. Thus began a lot of work.

Fortunately, I’d already bought an on-line copy of the engine’s service manual, and that gave quite a bit of information about dismantling it.

Here’s a record of the positions of the flywheel and timing wheel. The “T” lines up with one side of the middle pillar, while the dot on the wheel lines up with the other.

Off with the timing wheel.

Then I was able to remove the rocker box cover. These bolts came undone reasonably easily, though not completely smoothly. Inside you can see the rockers on the cam shaft, and the tops of the engine valves. Everything is nicely coated in engine oil.

Then it was time to undo the six head bolts. You can see one of them at the top-right of the rocker box in the picture above. The other five are recessed some way back. This was tricky. Four of the bolts made a nice click and came free. Two of them resisted. I wiggled them. We applied penetrating oil and cold shock. Then I wiggled them a bit more. And a bit more. And then they both sheared off.

Here’s what’s left of the middle-left bolt. The top-right bolt sheared some way down and so was less visible.

Even with the bolts broken, the engine head showed no sign of coming loose, even after some sharp taps with a mallet.

We rigged up some plates using the rocker box bolt holes and some studding to try to press down on the remains of the broken bolts and on the threads of the head bolt holes. By progressively tightening these against each other and tapping the head with a mallet, we hoped it would come loose.

Well, the plates buckled.

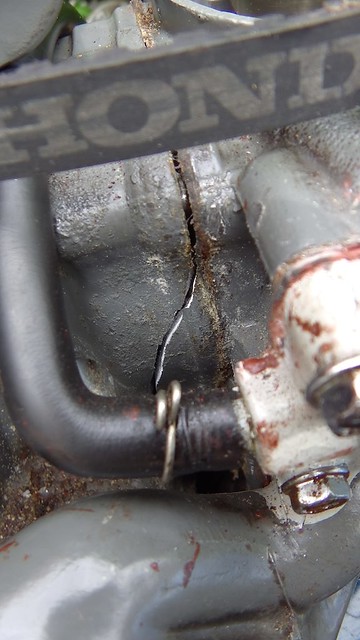

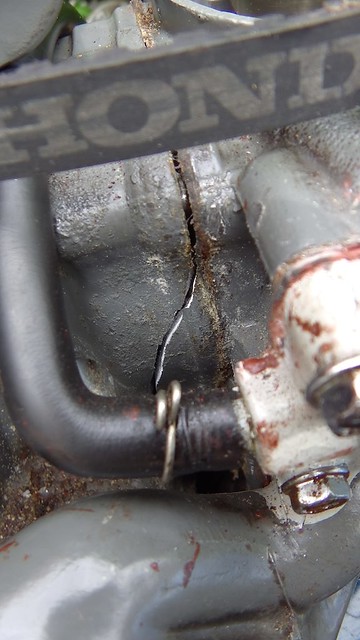

And then finally, the head came loose. I was very pleased for a few seconds until I realized just how it had happened. Can you see?

That’s a crack in the engine block. The middle left bolt hadn’t moved. Instead, the block cracked and the bolt took part of it away.

At this point I thought the engine was dead. A cracked block is pretty terminal. But I wasn’t prepared to give up completely, and in any case I wanted to find out what was wrong under that head!

Our next move was to drill out the bolts. We should have done this first, instead of trying to press them out, but we hoped we could avoid damage. Drilling out bolts is tricky and you usually end up with a larger hole than you want. Here’s a picture part-way through drilling out the top-right bolt, with some wooden wedges trying to persuade the head to come loose.

Finally, the bolt was cleared and the head came away. Now we could see what was going on inside the engine.

The first thing to note is the clean grey metal at the top edge. That’s the part of the block that cracked and came away with the head. It’s still attached to the middle-left broken head bolt.

You can also see that the upper cylinder exhaust valve is very different in appearance from the others. It was not coated with carbon. It was also not closing properly, and rotated in its seat. It’s likely the upper cylinder was not firing properly at all. This problem may have been caused by the next thing.

All that off-white junk around the cylinders is some kind of deposit from the water. It’s not meant to be there. Those are meant to be empty channels for cooling water to flow around the cylinders. The top cylinder isn’t getting any cooling. In fact, as I found out much later (after a lot of unclogging) this meant water was not circulating around the cylinders at all. It’s liklely that the only reason I hadn’t damaged the engine by overheating is that I never ran it for more than a few minutes at a time.

The material looked very old. I’m pretty sure it could not have accumulated in the engine while it was upright, since all the water flows down away from that spot. I suspect it is the result of the engine being stored with water in it, and then possibly a build-up over time.

And this is the cause of the water leak around the head. Water was trying to get past this clog, and had forced its way through the old gasket. The “corrosion” on the engine wasn’t from the aluminum (which is fine) but was more of this gunk from the water.

Here’s the corresponding part of the engine block. Again, those channels around the cylinders are supposed to be clear.

We took the head to the drill press and drilled out the middle-left head bolt, separating the broken piece of the engine block.

Having cleaned off the block, I noticed a second crack, tucked underneath the flywheel.

So now that flywheel has to come off. Yet again we are confronted with something that hasn’t moved for 30 years. The flywheel bolt required a huge amount of strength and a very long wrench to loosen, and then of course the flywheel itself refused to come off. Luckily Dad had a large bolt puller, and with a lot of tightening and persuasion with a mallet, the flywheel came loose.

At this point I spent a lot of time cleaning the white deposits out of the water channels using a mixture of pointy metal tools and stiff brushes. We did try dissolving the stuff using descaling acid, but it had no effect. Whatever it is, it’s very tenacious.

The water channels inside the head are quite convoluted, and it took some time before I understood how they connected up. I even sucked some cotton thread through the various tunnels with a vaccuum cleaner to try to figure it out. After a while I deduced that there must be a water exit hidden somewhere in the head, and decided to take off the manifold.

I found more water channels, fortunately clear of debris, and the key to the mystery: the clogged up thermostatic valve.

The way things work is this: the impeller pushes water through the engine. When it reaches the engine it has two ways to go: it can bypass more-or-less straight into the exhaust, or it can flow around the cylinders, past the thermostat, and into the exhaust. But when the engine is cold, the thermostat is closed. As the engine heats up (to about 80C) the thermostat opens and allows cooling water to flow around the cylinders. In this way the engine temperature is regulated.

Unless the thermostat is clogged.

I cleaned and tested the thermostat with hot water from the kettle. It was fine.

Then we tested the water flow through the engine by squirting it into the inlet using the garden hose.

All good. Now, what about those cracks?

After a bit of searching, I found out about aluminium brazing, and even found a brazing rod supplier near a friend’s house. I also bought a butane torch and attached it to my boat’s butane supply.

As a trial, I had a go at brazing a small piece of the head that I’d broken off with the mallet while trying to get it off. Here you can see it held by the mole grips.

This took a long time. I think it took over 45 minutes to get the head hot enough to melt the rod. I suspect my torch isn’t very good, but also the aluminium head was conducting the heat away quite efficiently. I needed to get the metal up to about 300C, and that proved very difficult. It worked eventually. Here’s a picture of the repair after some clean-up.

At this point I realized that I probably wasn’t going to be able to braze the cracks in the block. I wouldn’t be able to get the repair areas hot enough with my torch. Even if I could, the heat would be damaging other parts of the engine. I’d have to completely disassemble everything before I started. The amount of effort was starting to go from merely excessive to ridiculous.

In the meantime, another problem had emerged. I took the gearbox off the engine to gain access to the water inlet, and also to check the impeller. But I couldn’t get to the impeller, because the engine shaft was stuck fast on to the gearbox pinion shaft. There’s a simple square joint between them, but it wouldn’t budge.

I tried oil and hammers. I tried fire and ice.

Next, I tied icicle hitches around the shafts and applied a lot of force using a 2 tonnes hydraulic crane.

Nope. The main thing I learned from this is that icicle hitches are awesome. One of those hitches is tied to a highly polished smooth stainless-steel shaft!

Eventually I moved to applying force using just the 8 tonne hydraulic ram. The icicle hitch on the smooth end couldn’t quite cope with this, so a shackle was used around a narrowing in the shaft.

I’m not sure how much force I applied, but the 8 tonne ram was working hard. Still nothing.

The good thing about this is that it tested the black rope. This is rope that I bought to build my Jordan Series Drogue. I’m now very confident it’ll cope with Tammy Norie’s expected maximum 1 tonne load.

There were also some other attempts involving hanging the shaft from a chain, applying tension, and heating it. I suspect the only way to get enough concentrated heat would be using an induction coil.

Unforuntately, with this shaft fused together it’s impossible to change the impeller. An impeller failure at sea means an overheating engine. And so the engine was looking less and less viable.

Back to the cracked block. I decided I’d see if it could be repaired using an epoxy compound. Remember, the cracked aluminium parts are in the water jacket, not in the combustion cylinders, so they’re not under explosive engine pressure, so it’s plausible that an epoxy might work. After a bit of research I decided to try Plastic Padding Super Steel Epoxy Weld.

I bought flat steel section to ensure that my work ended up flat, and bolted the broken-off piece of engine block to it.

I attached this assembly to the engine, using the epoxy weld to seal the crack and re-attach the broken-off piece. The masking tape was to prevent the plate becoming bonded to the engine block.

I re-assembled the head, re-seated the valves, and made everything clean and beautiful. Then I put in a new gasket and bolted the engine back together.

In this picture you can see a modification to the middle-left head bolt. I drilled right through the block and added a nut at the back. This is because I did not feel I could rely on the epoxy weld under tension. The new arrangement compresses the broken-off piece to the block instead.

And finally, I tested it using butane as fuel.

It started easily, and ran beautifully.

And leaked water.

Unfortunately, the epoxy failed to seal the water channels. Although my work had cleared the water blockages, fixed the exhaust valve, improved compression, and made everything smooth, we still had a leaky engine with an unmaintainable impeller.

At this point I decided I’d had enough. Up to this point I was learning a lot about engines. I’d never dismantled and reassembled a cylinder head before, and it was all worth doing just for that. But now I was faced with doing it all again, with uncertain results.

Fortunately, on that day, another Honda BF100 appeared on eBay. The same engine. The one I’d just learned inside-out. What’s more, I had nearly a whole engine’s-worth of spares. It was ideal. So I bid, won, rented a car, and drove 450 miles to collect it.

That’s the engine that’s now in Tammy Norie.

As you can imagine, I was able to give it a very thorough service. And I made sure the head bolts turn!

Postscript: I think my problems with engines come partly from a design problem with the Coromandel. Having an outboard in a well is quite neat, but there’s no easy way to lift the engine out of the water when it’s not in use. A look around will quickly show you that everyone lifts their outboards. The gearbox and lower parts of the engine aren’t meant to spend their lives immersed in salt water. My problems with the shaft are the result. I have yet to come up with a neat solution.