I’ve been pondering new sails for Tammy Norie for some time. My goals are to increase performance in light winds and improve upwind performance while keeping things simple, strong, and maintainable. I believe that I’ll need to increase sail area and add camber to my sails to achieve this. I’ve briefly described various methods in my earlier post New Sails for Tammy Norie . I had more-or-less settled on an HHH system for simplicity and maintainability.

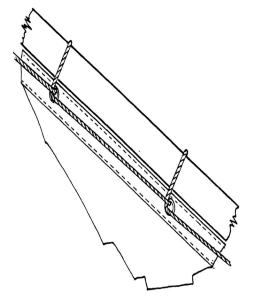

On Friday I was looking at figure 10.2 from Practical Junk Rig showing how to attach the sail to the yard.

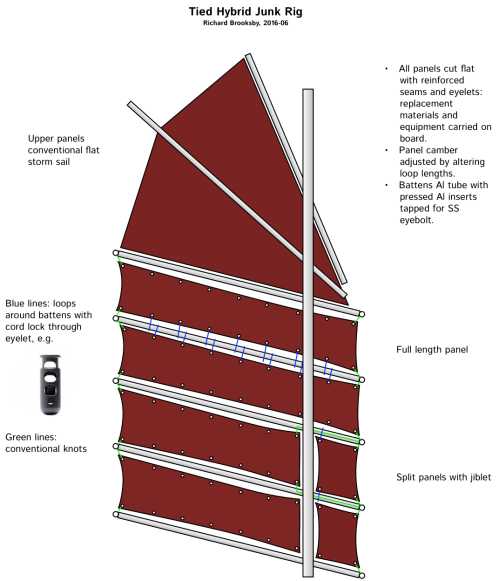

Then it struck me: why not attach all the panels to the battens with string? One weekend-long brainstorm later, and I present to you the Tied Hybrid system for Junk Rigs.

The idea is simple: cut the main panels flat with reinforced seams with eyelets. Then tie the panels to the battens with loops of cord. By adjusting the lengths of the loops you can adjust the camber of the sail in pretty much any way you like. Sprung cord locks allow you to do this easily, but you can of course use stopper knots. If the battens are smooth stainless steel tubes then the loops will slip round easily when tacking, flipping the sail camber to the other side.

In addition, it’s a simple matter to make split panels and get a split junk rig with jiblets. It wouldn’t even be very hard to carry both split and full-length panels on a voyage for different conditions. Since all the panels are the same you can get a lot of flexibility.

This is so simple that I have trouble believing that it hasn’t been tried and somehow failed. I’ll be interested in feedback from the members of the Junk Rig Association about that. If it hasn’t been done then I’ll definitely be giving it a go. It should be easy and cheap to construct, and allow for a lot of research into sail trim.

Ingenious, but won’t the gaps between the sections make it less efficient, by letting the pressure out? They might also be a bit noisy, if the wind whistles through them.

Yes, gaps are the most obvious drawback, and it could be that air pressure *through* the gaps will force the panels apart and mess up the sail shape too.

Great idea !! this sounds VERY interesting !

Interesting idea-definitely worth trying. I wouldn’t think the gaps will make any noticeable difference. There may possibly be some wind noise/flapping,but in practice one may well be reefed down if the wind is that strong. I doubt if you’ll notice.

An interesting project-go for it!

It looks a mix of Roger Taylor’s implementation on MingMing II and the David Ziegler Trilo junkrig setup. Very clever and a great illustration by the way. What tool do you use for that?

OmniGraffle https://www.omnigroup.com/omnigraffle/

Dave Zeiger responded to my thread on this topic at the JRA forums. You can read that here http://junkrigassociation.org/technical_forum/3399298?tpg=2&mlpg=3#3431363

Thanx for url! Funny to see how we are thinking on the same lines as far as the sail goes. I personally feel that your implementation is briliantly simple. What i do not see is how one could more or less “easily” swap panels – let’s say on top of the Doggers Bank.

I’m not really thinking it’d be *that* easy, more like something you’d do in port or at anchor. It’s still a lot easier than changing an entire sail. In an emergency, of course, you might be able to swap a panel on Dogger Bank!

Ironically I’ve been toying with exactly the same concept for some time, and share the same airflow concerns others have expressed here. It is definitely worth trying. It would be fun to build a small catamaran like the Rebel Cat just for this sort of experimentation. One could learn a great deal with little investment in materials and labor using painter’s dropcloth or poly tarp. Cost and time result in few true apples to apples comparisons.

H.W.

Hi,

As it happens, we have tried this to allow experimentation with different degrees of camber.

Implementation was a little tedious (lots of repetition) but simple enough. We used three round turns of a tarred, braided seine twine to form robands, ‘choked off under the grommet with clove hitches, each setting against the other. We used an offset board marked with the distance from batten to cloth at each interval.

Sailing (over a year, now) has been much improved over flat cut, despite the gaps. It’s held up in heavy blows with only the occasional replacement.

So it works… soon we’ll have a comparison with a solid, cambered sail.

Fair winds!

Dave Z

Hello Dave. Many thanks for posting your experience. I’ve watched your videos with interest and now I’ve found your blog. This seems like the sort of experiment you’d do. I’d be very grateful if you’d come back and let me know about your comparison, either here or with a link to your own post about it. I’ve unfortunately been too ill to make much progress with building a new sail, but I’m recovering and may be able to get to it next year.

Sorry to hear of your illness! Here’s to a full recovery!

I’m just now back in internet range and will do more of a writeup on it, probably for the JRA. In the meantime, here’s the text from a comment on your JRA Forum thread (https://junkrigassociation.org/technical_forum/3399298?mlpg=3#8083345):

“We made three round turns at each grommet forming a roband of sorts, then choked it of with clove hitches set against one another just below the cloth. This allowed the turns to rotate. We’ve had to replace two which chafed (before full failure), and none have untied.

The main is cambered split junk rig, with the after parallelogram panels lashed for 8% camber. The mizzen is lashed with marline hitches for 0% camber (flat).

Both depend from lashed ‘crab claw’ upper panels, which are flat cut. This acts like a ‘headboard… stress is evenly distributed and we’ve observed no topping up problems. They take their shape from conic section, and are our heavy weather ‘last sail standing’.

Our performance was much improved on our previous flat cut sails. We could point higher or sail with more power into the wind, with improved ghosting.

This despite not tweaking out some minor set issues (e.g., our roping should have crossed the battens at an angle, rather than perpendicular… as is, there is a zig zag introduced which interferes with a good set.

We’re planning on sewing final sails (SJR main with no gaps and cambered mizzen) this winter.

PS. I also heard lashing separate panels called ‘Thai style lashing’, though without reference to camber. It may well have been featured in The Last Sailors, narrated by Orson Welles. From way early on, anyway, before I myself had come around!”

For the record, Dave Zeiger has implemented just about everything I mentioned in this article and written it all up. You can see his write-up here https://docs.google.com/document/d/1gh4wS9K72GTQQeRACcOqSRV7WV87-5g8-Z0Yz9x8Zx4/edit and it will also be published in the JRA Magazine. There is also more discussion and feedback in the thread on the JRA forums here https://junkrigassociation.org/technical_forum/3399298 . Dave has implemented and tested pretty much everything I thought of. Fantastic!